alfredo@lanxiangguildinggroup.com

laurie@lanxiangbuildinggroup.com

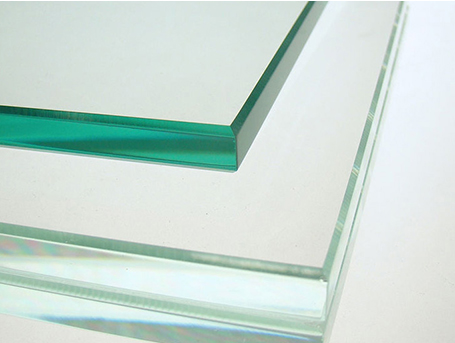

Clear float glass – White glass

Product Description

Tinted float glass is formed when the molten glass enters the tin bath via control gate and then enters the cooling bath after floats on the surface of molten tin under the action of centrifugal force and its surface tension, to get the two sides of glass to be smooth and even and ripple to disappear.

Characteristic

Smooth surface with no ripple, good perspectivity; flexible specification to reduce slice loss; glass with the thickness of 2-19mm and super-long super-large plate glass are available.

Purpose

For buildings; For mirrors; For furniture and decoration; For optical instrument; For automobiles

Thickness Range

2mm-19m